MEETING DEADLINES: A Look Into the Print Process Behind ISSUE 06 of SUSPEND Magazine

I remember the euphoric feeling I had when I first held the one-off copy of ISSUE 03 back in 2013, flipping through a physical version of a magazine that prior to those seconds had only existed as an online PDF, meant to be viewed by left-and-right clicks of a mouse button. I had no knowledge of print margins, font families, and "gutters" or "bleeds". With ISSUE 04 and ISSUE 05, the print process was still a mystery to me, and all the representatives I had ever dealt with existed as e-mail signatures. (ISSUE 05, to be fair, was printed in Barcelona, Spain.)

Now for the first time, however, I feel like SUSPEND has found a real home. We have a dedicated printshop in Culver City who is kind enough to open its facility to show us exactly what goes on when we finally hit that e-mail saying, "Let's go to print." Here, we invite you – our readers – a firsthand look at what happens after the all the editorials are laid out, all the copy is proofread, all the margins are fixed, all the names and spellings of individuals are checked over and over (and over), and when all the 148 pgs. of content comprising ISSUE 06 is good to go.

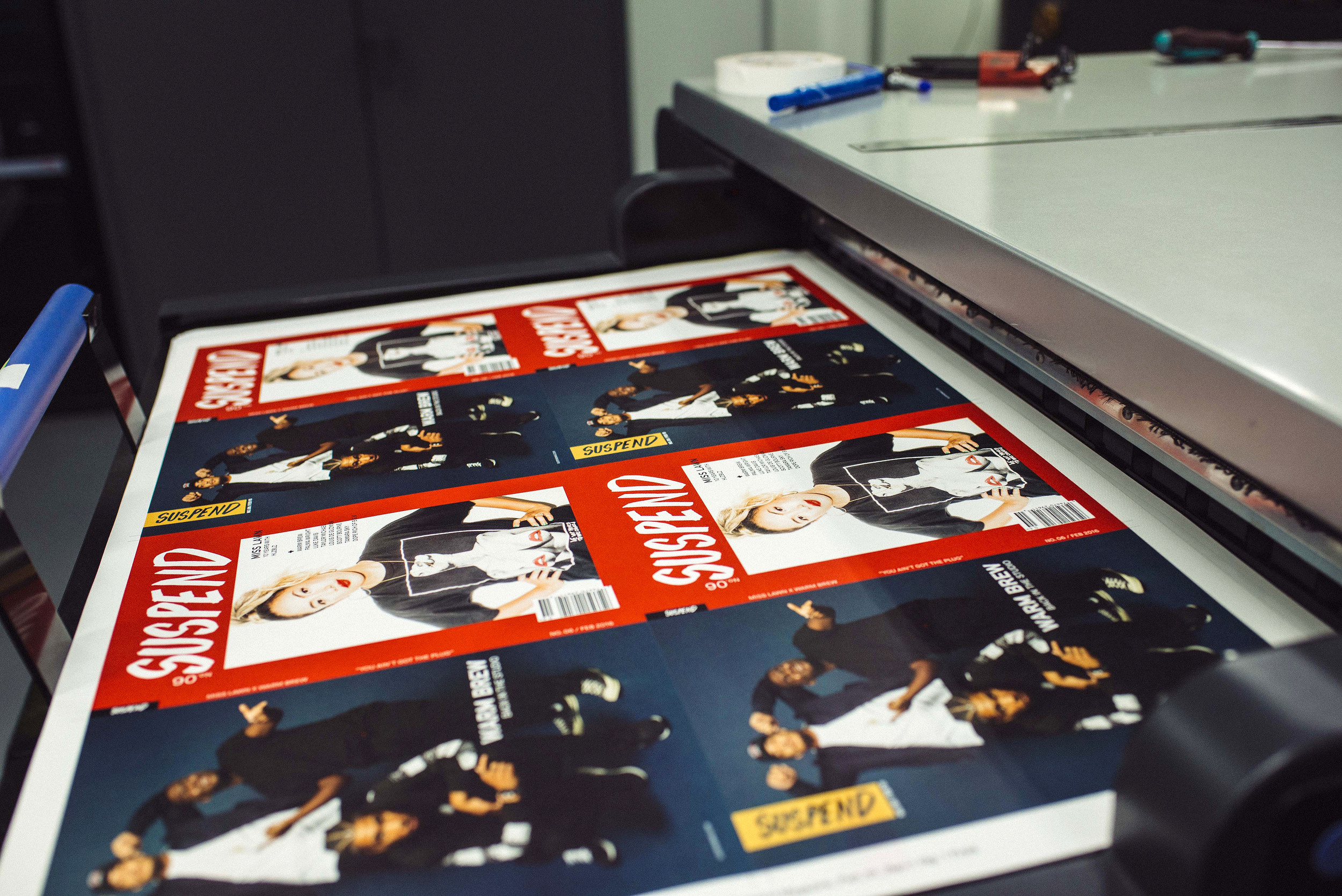

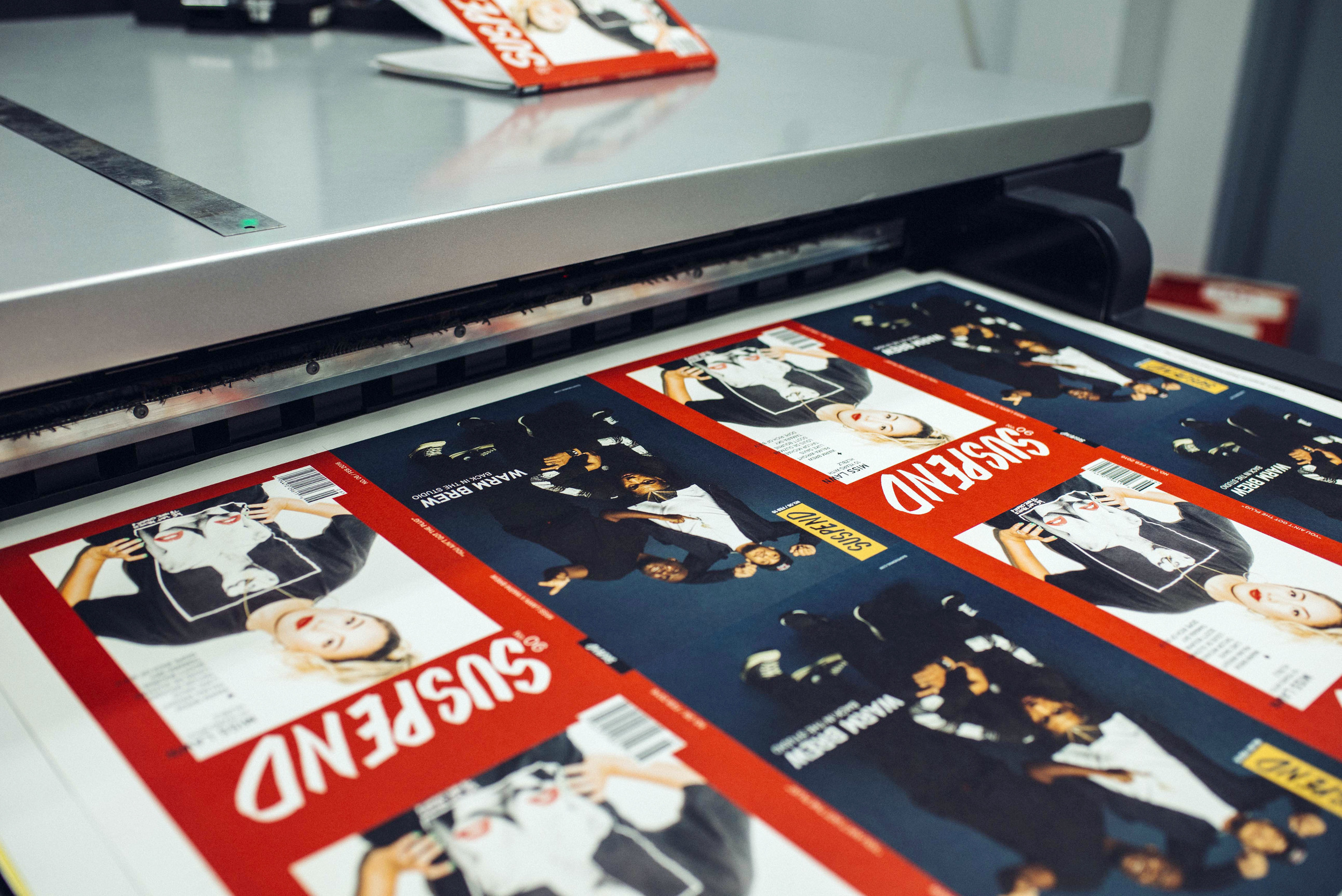

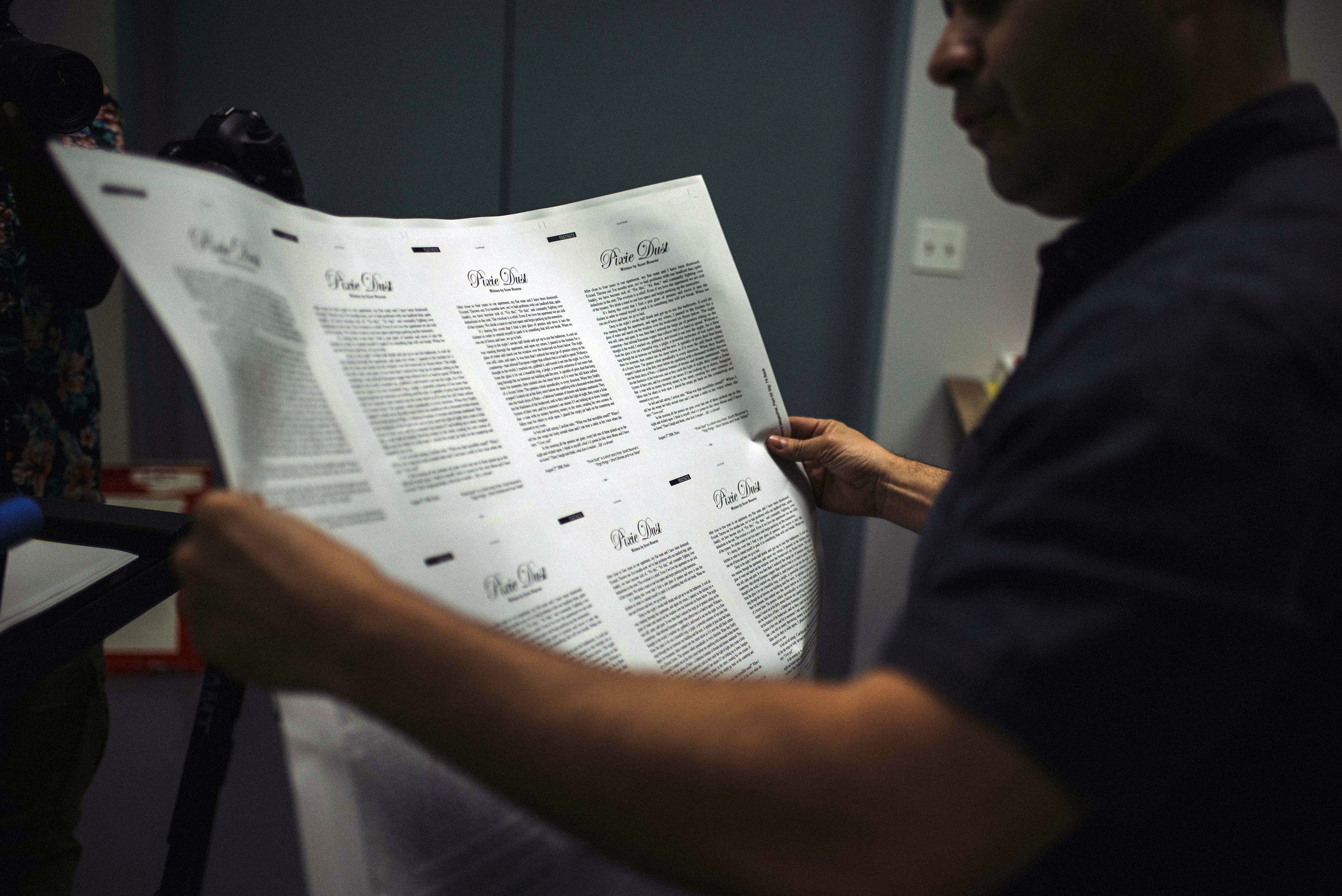

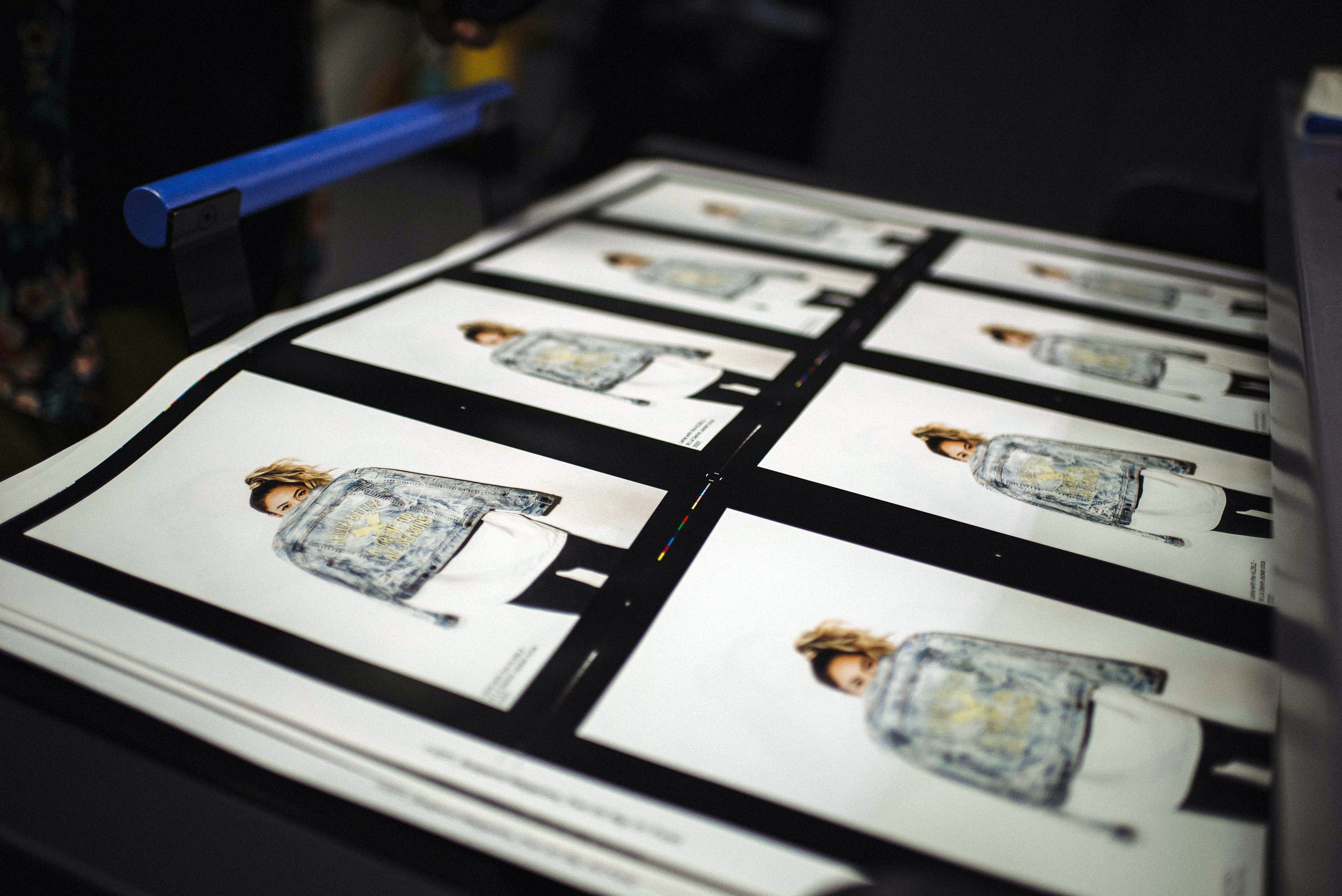

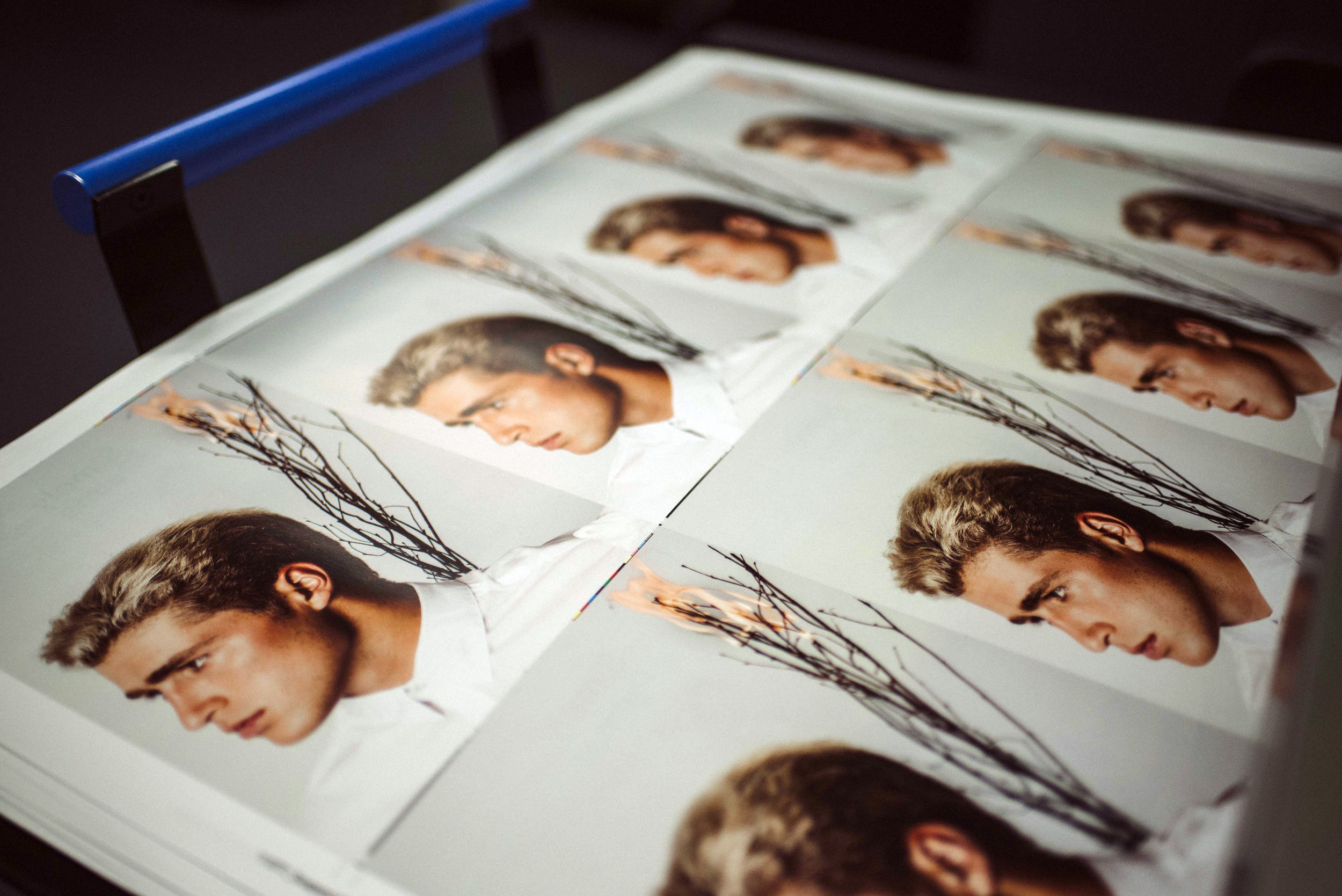

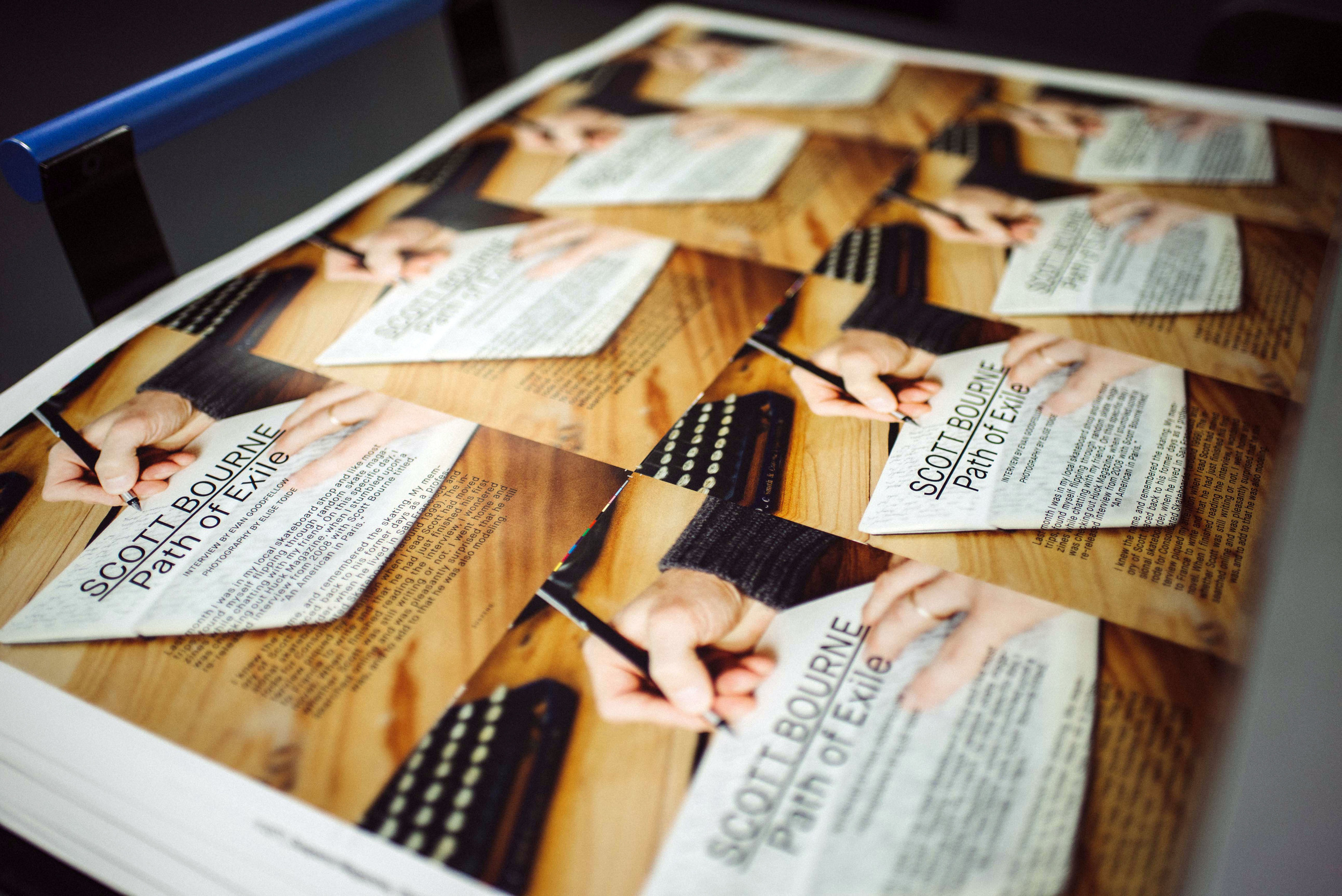

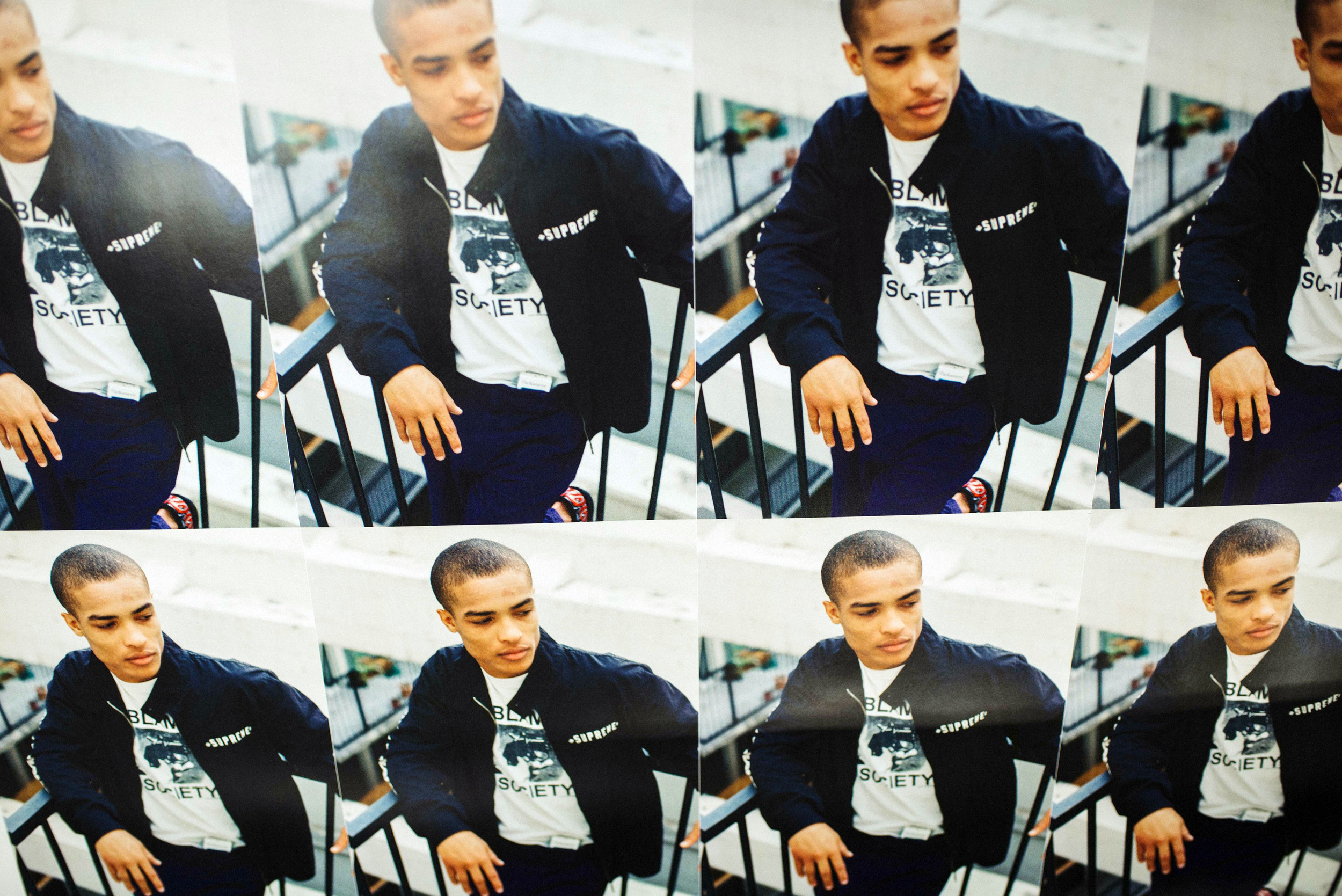

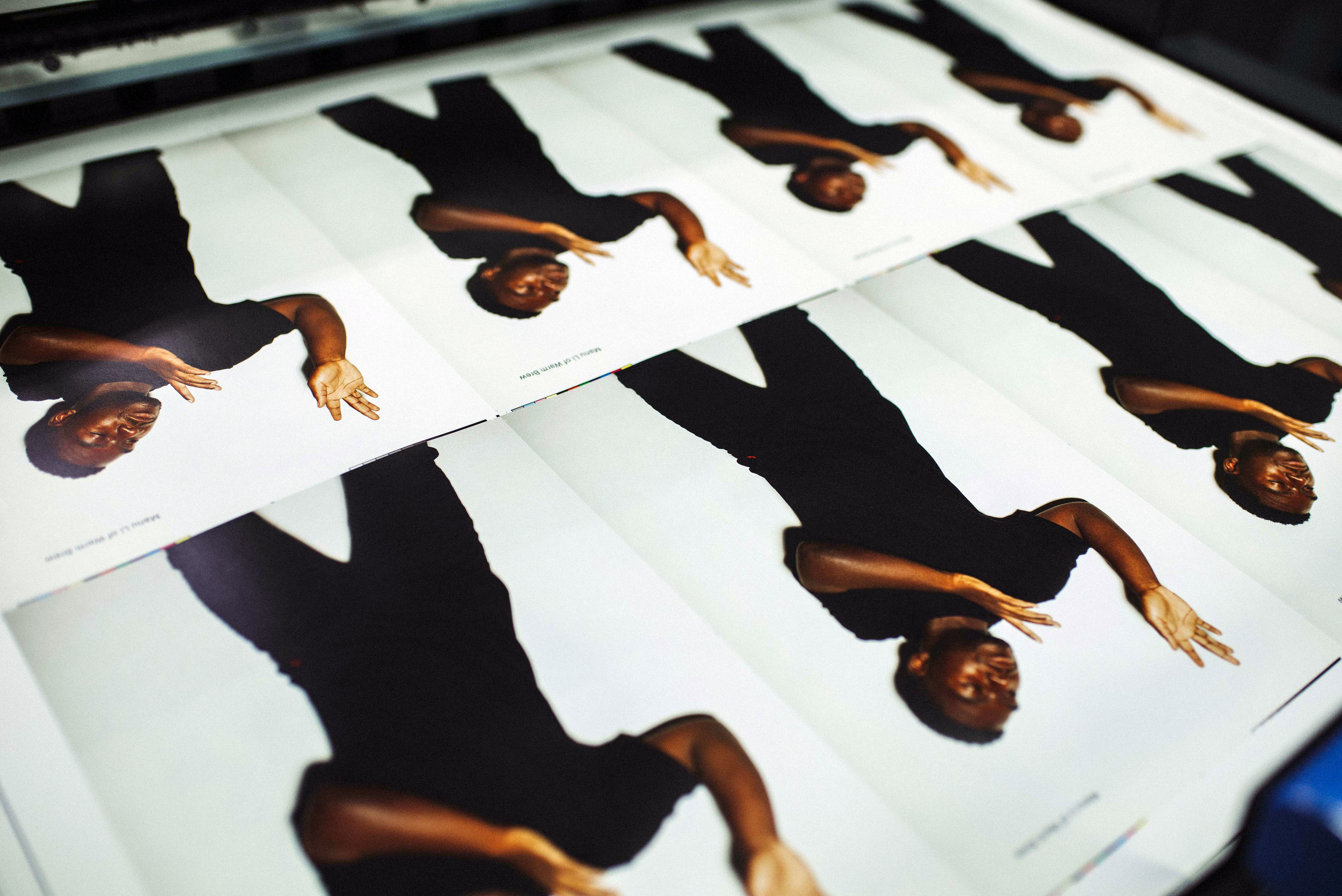

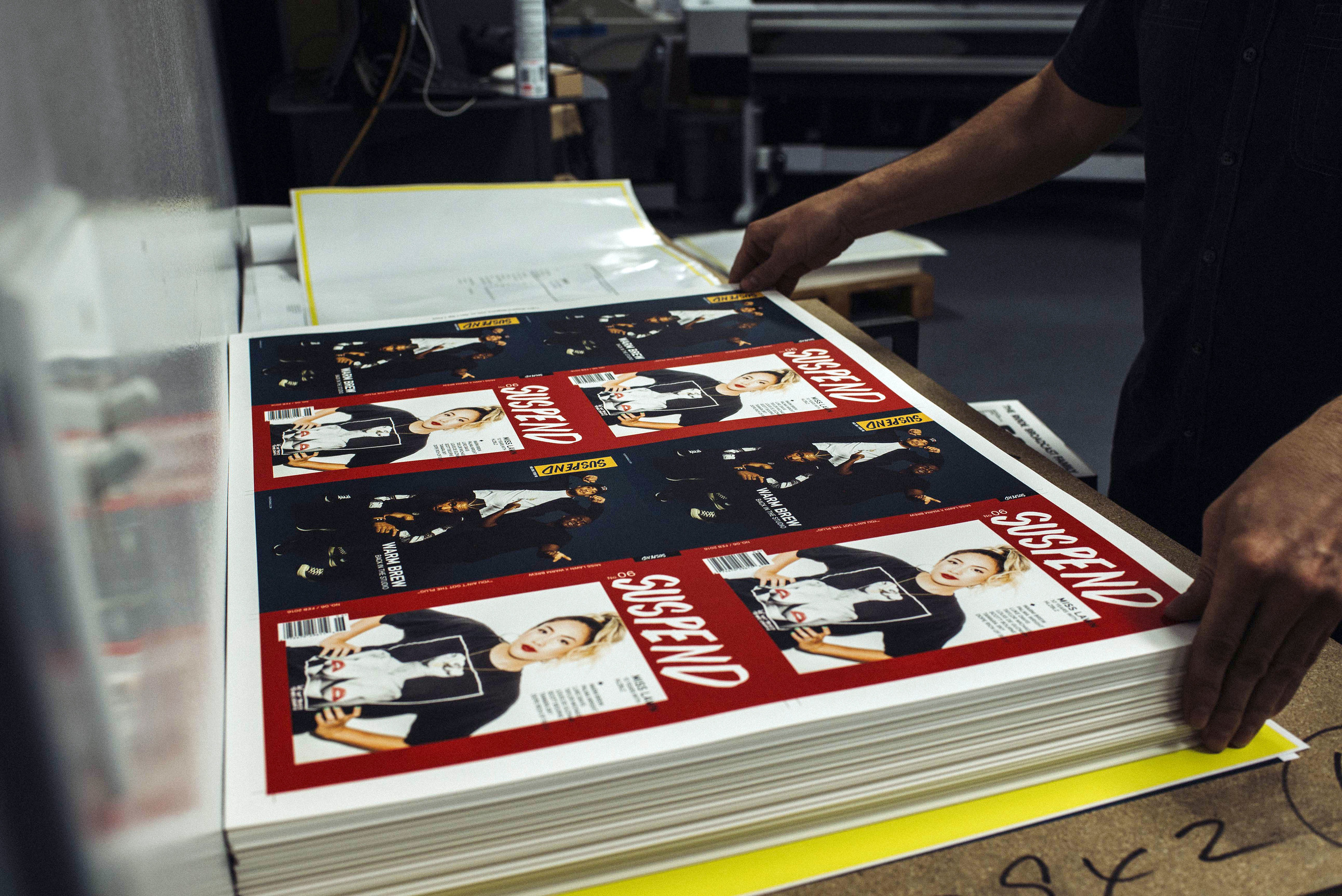

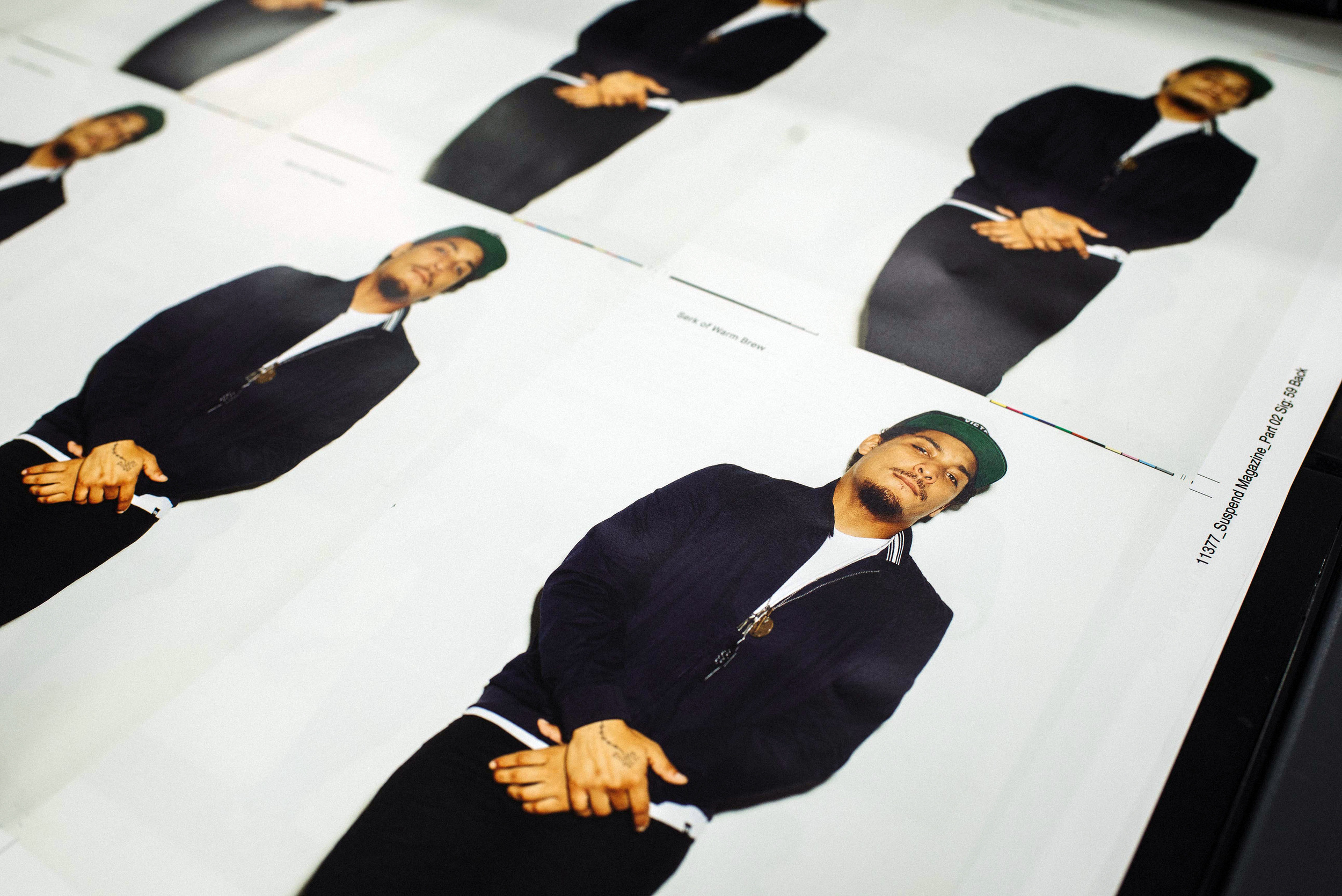

Here, you see oversized sheets printing several pages side-by-side to be stacked and then sent to a different area of the facility to be trimmed and bound together according to pagination. Our first dual cover with Miss Lawn of HLZBLZ and Warm Brew stands as a moment in our brief history as a publication with these two entities appearing next to each other for the first time in print.

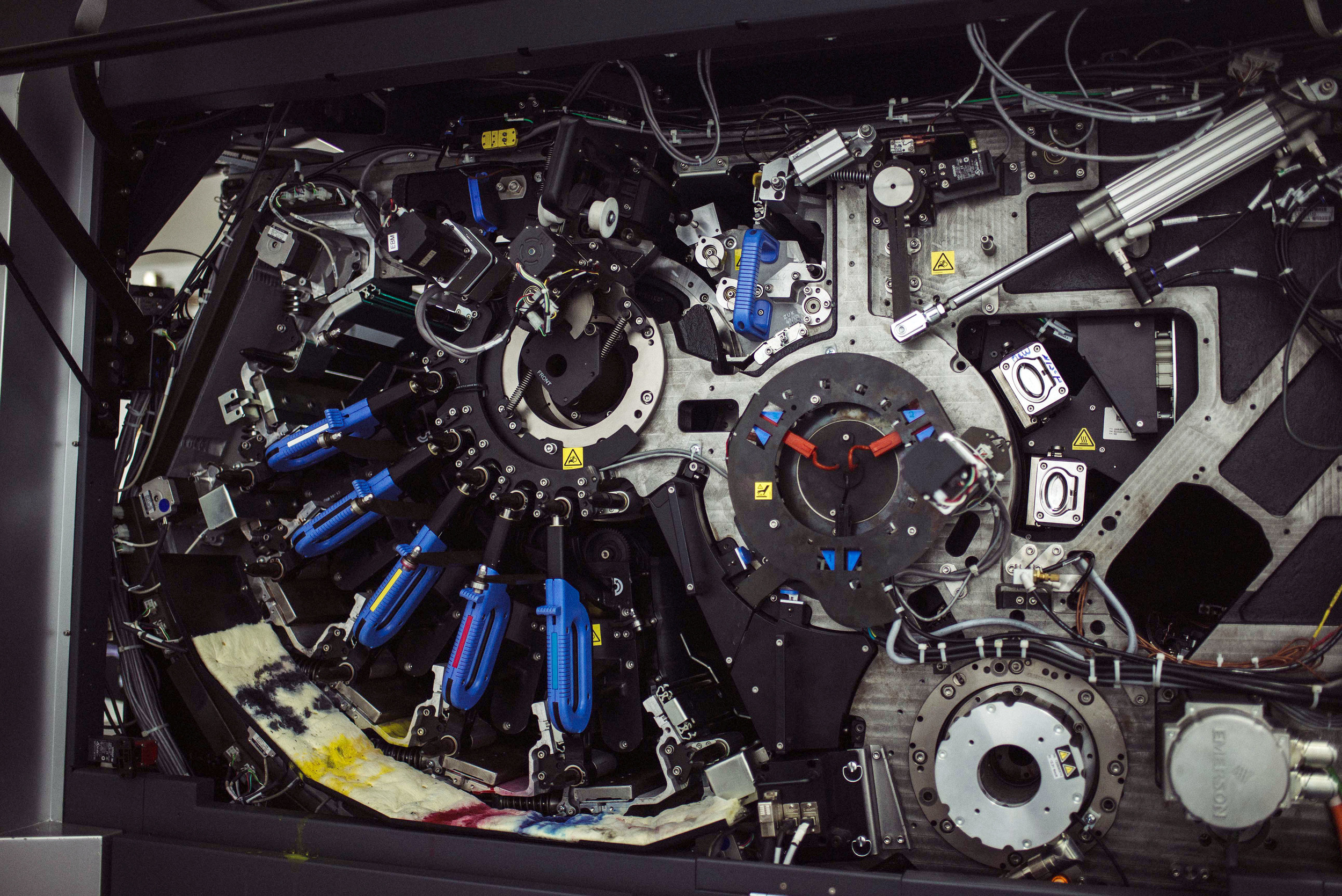

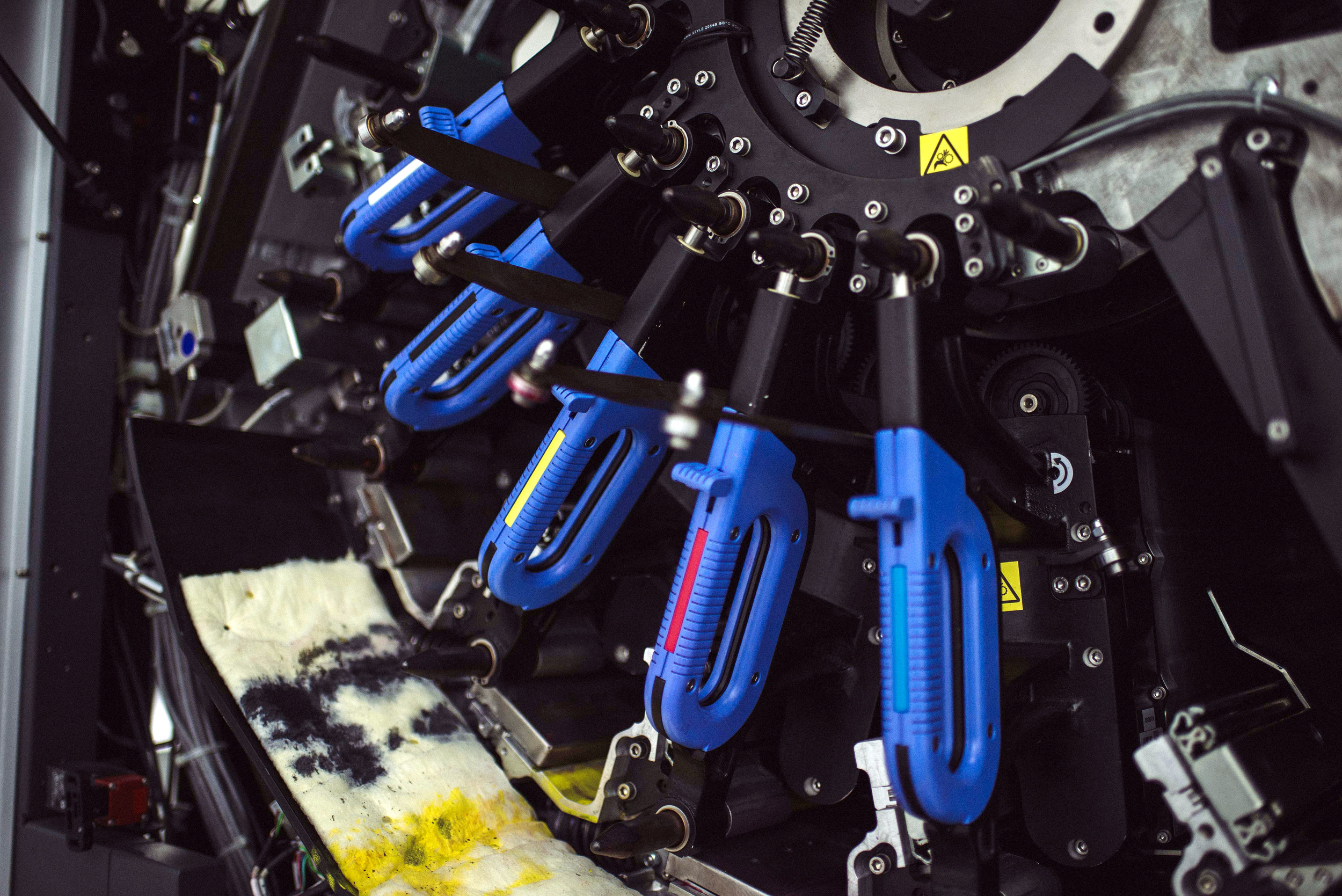

The technician surveys the ink levels and opens up the hatch door to show us the inner mechanism where the ink is deposited at lightning speed onto the sheets of paper by color.

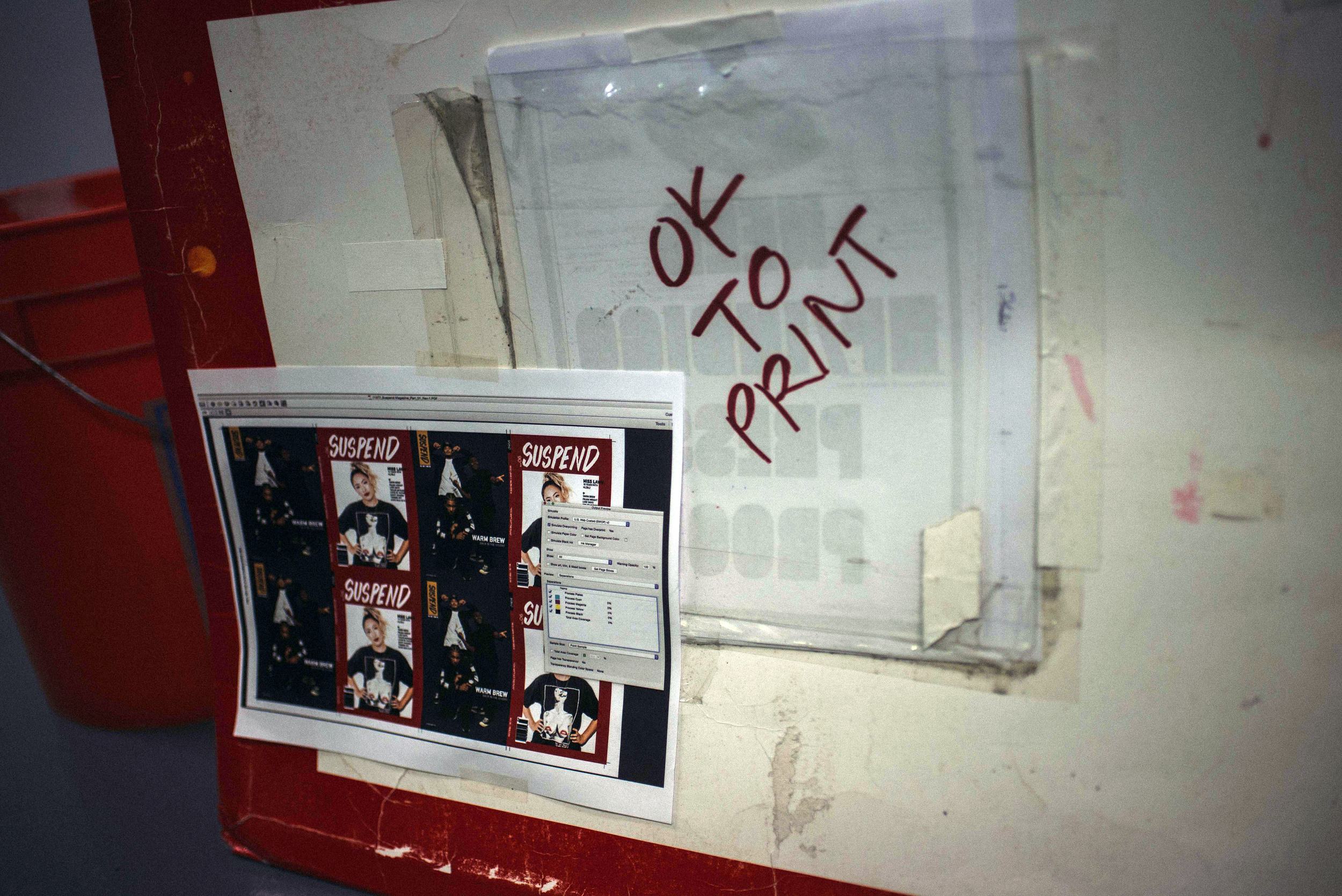

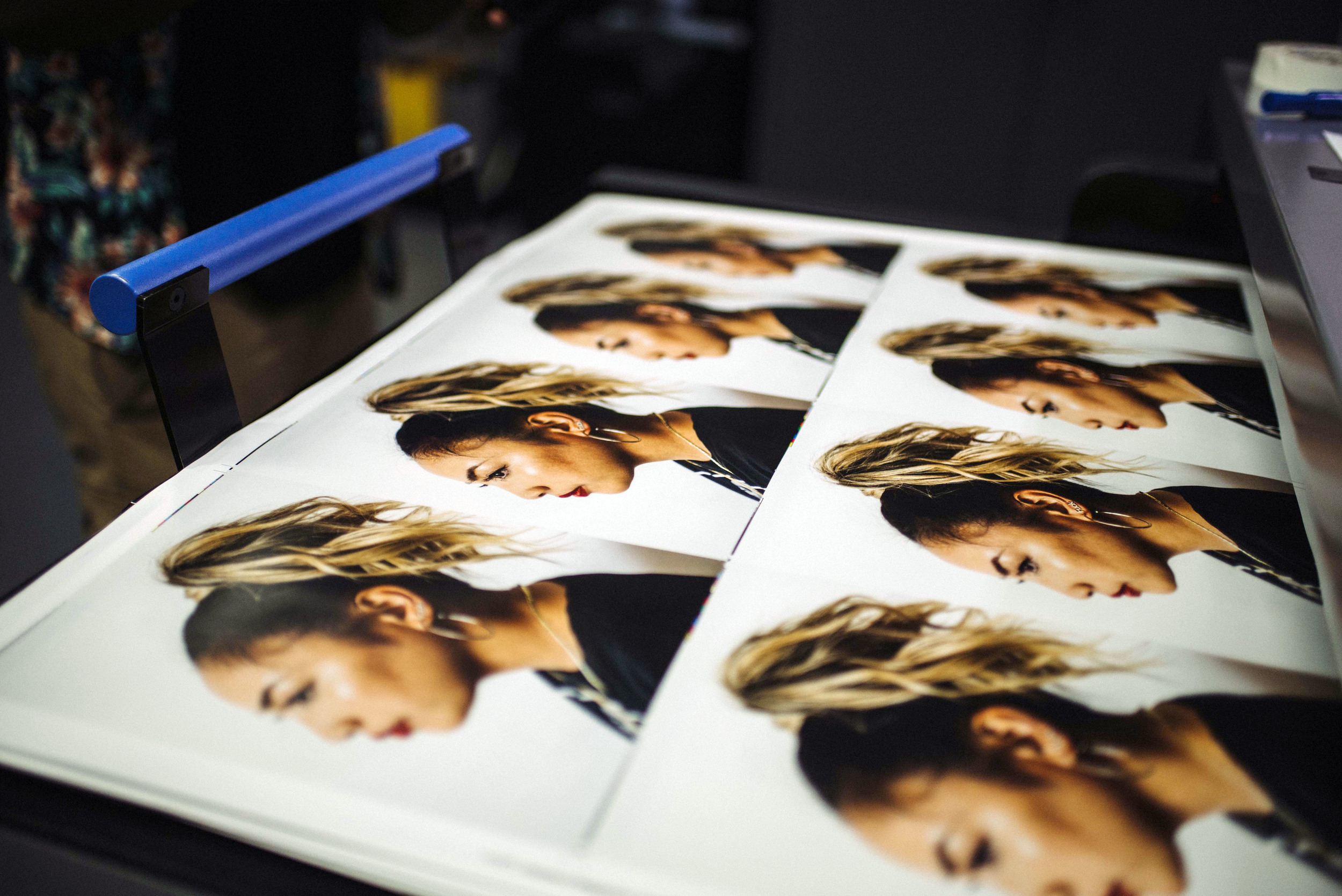

The technician prints out sheets from ISSUE 06 and inspects each one to make sure color, sharpness, and tones are achieved for topnotch print quality. He continues to monitor ink levels as each stack of sheets is churned out.

The technician has an unbound sample proof he uses as reference while the sheets are being prepared sheet by sheet.

After each batch of sheets is completed, the technician aligns the entire stack in one corner and prepares them for transport to the cut and trimming department where the binding takes place for ISSUE 06.

Photography and Text by Diane Abapo

Follow Diane on Instagram at @dianeabapo